A properly functioning dryer lint filter is essential for maintaining your appliance's efficiency and preventing potential safety hazards. When your dryer lint filter becomes clogged or damaged, it can significantly impact drying performance, increase energy consumption, and even pose fire risks. Understanding how to select the right replacement filter for your specific dryer model ensures optimal performance and extends the lifespan of your appliance.

Understanding Dryer Lint Filter Components

Filter Construction Materials

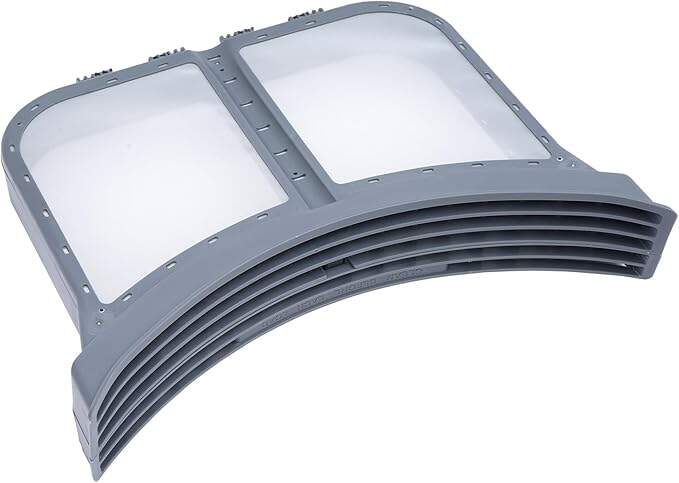

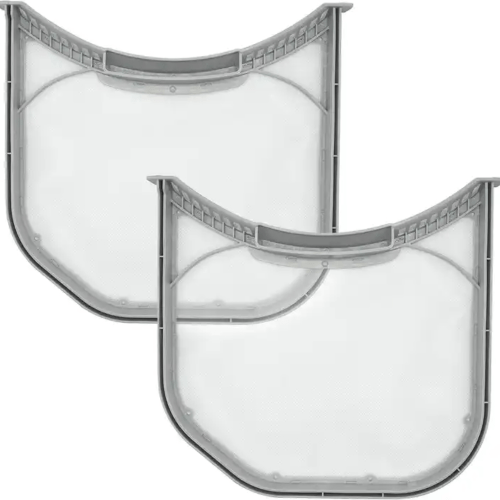

Modern dryer lint filters are typically constructed from high-quality mesh materials designed to capture lint particles effectively while maintaining adequate airflow. The mesh density plays a crucial role in filtration efficiency, with finer meshes capturing smaller particles but potentially restricting airflow if not properly maintained. Most dryer lint filter assemblies feature aluminum or stainless steel frames that provide structural integrity and resist corrosion from moisture and heat exposure.

The filter screen material itself varies between manufacturers, with some utilizing woven polyester mesh and others employing metal screening. Quality dryer lint filter designs incorporate reinforced edges to prevent tearing during installation and removal. The frame construction must withstand repeated handling and the thermal cycling that occurs during normal dryer operation.

Frame Design Specifications

The frame design of a dryer lint filter directly impacts its compatibility with specific dryer models. Dimensional accuracy is critical, as even slight variations can result in improper sealing or installation difficulties. Manufacturers engineer filter frames with precise tolerances to ensure proper fit within the filter housing and maintain optimal seal integrity around the perimeter.

Handle placement and ergonomics also vary among different dryer lint filter designs. Some models feature center-mounted handles for balanced removal, while others incorporate side-mounted or recessed grips. The handle design affects both user convenience and the overall structural integrity of the filter assembly during extended use.

Compatibility Requirements for Different Dryer Models

Brand-Specific Filter Variations

Each dryer manufacturer implements unique filter specifications that must be matched precisely when selecting a replacement dryer lint filter. LG dryers, for example, utilize specific filter dimensions and mounting configurations that differ from other brands. The filter housing design varies between manufacturers, requiring careful attention to compatibility specifications to ensure proper fit and function.

Kenmore dryers often share compatibility with other brands due to manufacturing partnerships, but verification of specific model numbers remains essential. Cross-referencing part numbers and model compatibility ensures that the selected dryer lint filter will function correctly with your specific appliance. Many aftermarket filters offer compatibility with multiple brands, providing cost-effective replacement options.

Model Number Identification

Accurate model identification forms the foundation of successful dryer lint filter selection. Dryer model numbers are typically located on a label inside the door frame or on the rear panel of the unit. This information enables precise matching with compatible filter assemblies and ensures optimal performance.

Part number cross-referencing helps identify suitable replacement options when original manufacturer parts are unavailable or cost-prohibitive. A quality dryer lint filter replacement will include comprehensive compatibility information to simplify the selection process for consumers.

Performance Characteristics and Efficiency Factors

Airflow Management

Optimal airflow through the dryer lint filter is essential for efficient moisture removal and proper dryer operation. A clogged or improperly designed filter restricts airflow, forcing the dryer to work harder and consume more energy. Quality filter designs balance particle capture with minimal airflow resistance to maintain system efficiency.

The mesh pattern and open area percentage directly influence airflow characteristics. Filters with inadequate open area create backpressure that reduces overall system performance. Conversely, filters with excessive openings may allow lint particles to bypass filtration, potentially causing downstream issues in the exhaust system.

Lint Capture Efficiency

Effective lint capture prevents particles from accumulating in the exhaust ductwork and reduces fire risk associated with lint buildup. A properly functioning dryer lint filter should capture the majority of lint particles generated during the drying process while maintaining reasonable airflow levels.

Filter efficiency varies based on mesh density, material composition, and overall design quality. High-efficiency dryer lint filter assemblies incorporate multiple capture mechanisms to ensure comprehensive particle removal across different lint sizes and types. Regular filter cleaning and timely replacement maintain optimal capture efficiency throughout the filter's service life.

Installation Considerations and Maintenance Requirements

Proper Installation Procedures

Correct installation of the dryer lint filter ensures optimal performance and prevents operational issues. The filter must seat properly within the housing to maintain an effective seal around the perimeter. Improper installation can result in air bypass, reduced filtration efficiency, and potential damage to the filter assembly.

Before installing a new dryer lint filter, thoroughly clean the filter housing to remove accumulated lint and debris. This preparation ensures proper seating and prevents contamination of the new filter. Verify that the filter orientation matches the housing design and that all mounting features align correctly during installation.

Maintenance Schedule and Cleaning

Regular maintenance of the dryer lint filter is crucial for sustained performance and safety. Cleaning the filter after each dryer cycle prevents excessive lint accumulation and maintains optimal airflow. Remove visible lint by hand or with a soft brush, avoiding aggressive cleaning methods that might damage the mesh material.

Periodic deep cleaning using warm water and mild detergent helps remove fabric softener residue and other contaminants that can reduce filter effectiveness. Allow the dryer lint filter to dry completely before reinstallation to prevent moisture-related issues. Inspect the filter regularly for signs of wear, damage, or deterioration that might necessitate replacement.

Cost Analysis and Value Considerations

Initial Investment Factors

The cost of a replacement dryer lint filter varies significantly based on brand, quality, and compatibility requirements. Original equipment manufacturer filters typically command premium prices but offer assured compatibility and performance. Aftermarket alternatives may provide substantial cost savings while maintaining acceptable quality standards.

When evaluating dryer lint filter options, consider the total cost of ownership including expected service life and maintenance requirements. Higher-quality filters may justify increased initial costs through extended durability and superior performance characteristics. Factor in potential energy savings from improved efficiency when calculating overall value.

Long-term Economic Benefits

Investing in a quality dryer lint filter can generate significant long-term savings through improved energy efficiency and reduced maintenance costs. Proper filtration reduces strain on the dryer motor and heating elements, potentially extending their service life. Effective lint capture also minimizes the risk of exhaust system blockages that require professional cleaning services.

The prevention of lint-related dryer fires represents an invaluable safety benefit that far exceeds the cost of proper filter maintenance. Insurance implications and potential property damage costs underscore the importance of maintaining an effective dryer lint filter system throughout the appliance's operational life.

Safety Considerations and Fire Prevention

Lint Accumulation Hazards

Lint accumulation poses serious fire risks that make proper dryer lint filter maintenance a critical safety concern. The U.S. Fire Administration reports thousands of dryer fires annually, with failure to clean filters being a leading cause. Lint particles are highly combustible and can ignite when exposed to the high temperatures generated during dryer operation.

A compromised dryer lint filter allows particles to bypass filtration and accumulate in the exhaust system, creating fire hazards throughout the venting pathway. Regular filter inspection and prompt replacement when wear becomes evident helps maintain the primary line of defense against lint-related fires.

Warning Signs and Indicators

Several warning signs indicate potential issues with dryer lint filter performance that require immediate attention. Extended drying times, excessive heat buildup, and burning odors during operation all suggest possible filter problems or lint accumulation. Visible lint deposits around the dryer or on clothing after drying cycles indicate compromised filtration.

Monitor the dryer lint filter condition regularly and replace it immediately if damage becomes apparent. Tears, holes, or significant deformation compromise filter effectiveness and create safety risks. Establish a replacement schedule based on usage patterns and filter condition to maintain optimal safety standards.

FAQ

How often should I replace my dryer lint filter

A dryer lint filter should typically be replaced every 6-12 months depending on usage frequency and washing habits. Heavy use or washing items that generate significant lint may require more frequent replacement. Inspect the filter monthly for signs of wear, tears, or reduced effectiveness and replace immediately if damage is detected.

Can I use a generic dryer lint filter instead of the original manufacturer part

Generic dryer lint filter options can provide acceptable performance when properly matched to your dryer model specifications. Ensure that dimensional compatibility, mesh density, and construction quality meet or exceed original equipment standards. Verify compatibility through part number cross-reference or manufacturer specifications before installation.

What causes excessive lint buildup despite regular filter cleaning

Excessive lint accumulation may indicate issues beyond filter maintenance, including damaged filter mesh, improper installation, or problems with the exhaust system. Check for tears or deformation in the dryer lint filter assembly and ensure proper seating within the housing. Blocked exhaust venting can also create backpressure that affects filter performance.

Is it safe to run the dryer without a lint filter temporarily

Operating a dryer without a lint filter poses serious safety risks and should never be attempted. The absence of filtration allows lint to accumulate throughout the exhaust system, creating significant fire hazards. Always ensure a properly functioning dryer lint filter is installed before operating the appliance, and avoid using damaged or compromised filters.