Home fire safety begins with understanding the hidden dangers lurking in everyday appliances, particularly your clothes dryer. Each year, thousands of residential fires originate from poorly maintained laundry equipment, with lint accumulation being the primary culprit. A properly functioning dryer lint filter serves as your first line of defense against these potentially catastrophic incidents. Regular maintenance and replacement of this crucial component can significantly reduce fire risks while improving your dryer's efficiency and extending its operational lifespan.

Understanding Fire Hazards in Clothes Dryers

The Science Behind Lint Combustion

Lint consists of tiny fabric fibers that separate from clothing during the drying process, creating a highly flammable material when accumulated in sufficient quantities. These microscopic particles possess a large surface area relative to their mass, making them exceptionally susceptible to ignition. When exposed to the high temperatures generated by dryer heating elements, typically ranging from 125 to 135 degrees Fahrenheit, lint can reach its flash point and spontaneously combust. The combination of heat, oxygen, and combustible material creates the perfect storm for fire development.

Research conducted by fire safety organizations demonstrates that lint ignites at temperatures significantly lower than many other household materials. The fibrous structure allows for rapid flame propagation, enabling fires to spread quickly throughout the dryer system and potentially into surrounding areas. Understanding this fundamental fire triangle helps homeowners appreciate why maintaining a clean dryer lint filter represents such a critical safety measure in preventing residential fires.

Statistical Evidence of Dryer-Related Fires

According to the National Fire Protection Association, clothes dryers and washing machines cause an average of 15,970 home structure fires annually in the United States. These incidents result in approximately 13 civilian deaths, 444 civilian injuries, and $238 million in direct property damage each year. The overwhelming majority of these fires, roughly 92 percent, involve clothes dryers specifically, with failure to clean being the leading contributing factor in 34 percent of cases.

These statistics underscore the critical importance of proper dryer maintenance, particularly regarding lint management systems. The data reveals that most dryer fires are entirely preventable through routine cleaning and maintenance procedures. Homeowners who neglect their dryer lint filter replacement and cleaning routines significantly increase their risk of experiencing a devastating house fire that could have been easily avoided through simple preventive measures.

How Dryer Lint Filters Function

Mechanical Filtration Process

A dryer lint filter operates through mechanical filtration, capturing airborne particles as heated air circulates through the drum during the drying cycle. The filter typically consists of a fine mesh or perforated screen designed to trap lint while allowing air to pass through freely. As clothes tumble and generate friction, microscopic fabric fibers become suspended in the heated airflow and accumulate on the filter surface, preventing them from entering the exhaust system.

The effectiveness of this filtration process depends heavily on proper airflow dynamics within the dryer system. When the dryer lint filter becomes clogged with accumulated debris, air circulation becomes restricted, causing the system to work harder and generate additional heat. This increased thermal load not only reduces drying efficiency but also creates dangerous conditions where lint buildup can reach ignition temperatures more easily.

Filter Design and Materials

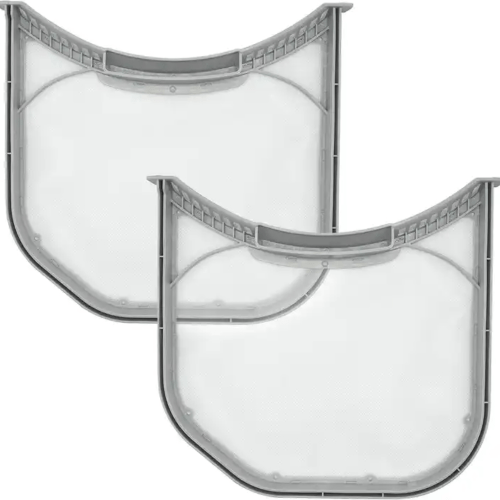

Modern dryer lint filters utilize various materials and construction methods to optimize particle capture while maintaining adequate airflow. Most filters feature aluminum or plastic frames supporting fine mesh screens made from synthetic materials or metal wire. The mesh density is carefully engineered to balance filtration efficiency with air permeability, ensuring maximum lint capture without significantly impeding the drying process.

Advanced filter designs incorporate multiple layers or specialized coatings to enhance performance and durability. Some filters include antimicrobial treatments to prevent bacterial growth in the moist environment, while others feature reinforced edges to prevent tearing during handling. Understanding these design elements helps consumers select appropriate replacement filters and appreciate the engineering that goes into these seemingly simple but crucial safety components.

Fire Prevention Through Proper Maintenance

Regular Cleaning Protocols

Establishing a consistent cleaning routine for your dryer lint filter represents the most effective strategy for preventing fire hazards. Industry experts recommend removing and cleaning the filter after every load, regardless of the amount of visible lint accumulation. This practice ensures optimal airflow and prevents the gradual buildup of particles that can escape initial detection but contribute to long-term fire risk.

The cleaning process involves more than simply removing visible lint from the filter surface. Proper maintenance includes washing the filter monthly with warm water and mild detergent to remove fabric softener residue and other substances that can clog the mesh pores. These deposits may not be immediately visible but can significantly reduce filtration efficiency and contribute to restricted airflow that increases fire risk over time.

Professional Maintenance Considerations

While homeowner maintenance addresses most routine cleaning requirements, professional servicing provides comprehensive system evaluation and deep cleaning that extends beyond the dryer lint filter. Professional technicians can access and clean internal ductwork, inspect heating elements, and identify potential problems before they develop into safety hazards. This comprehensive approach ensures all system components work together effectively to minimize fire risk.

Professional maintenance services typically recommend annual inspections for most households, with more frequent servicing for high-usage situations. These evaluations include checking exhaust vent functionality, measuring airflow rates, and testing safety systems that may not be accessible during routine homeowner maintenance. Investing in professional maintenance provides additional peace of mind and helps ensure long-term system safety and efficiency.

Warning Signs of Filter Problems

Performance Indicators

Several observable symptoms indicate potential problems with your dryer lint filter that require immediate attention to maintain fire safety. Longer drying times represent the most common early warning sign, as restricted airflow forces the system to run extended cycles to achieve proper moisture removal. Clothes that remain damp or require multiple cycles to dry completely suggest significant airflow restrictions that could indicate filter problems or excessive lint accumulation.

Temperature-related symptoms provide additional warning signs of potential filter issues. If the dryer exterior becomes excessively hot during operation, or if clothes emerge from completed cycles hotter than normal, these conditions suggest inadequate heat dissipation caused by restricted airflow. The laundry room may also feel unusually warm or humid during dryer operation, indicating that heated air is not being properly exhausted from the system due to filter or ventilation problems.

Physical Inspection Criteria

Regular visual inspection of your dryer lint filter reveals important information about its condition and effectiveness. A properly functioning filter should appear relatively clean after each load, with only minimal lint accumulation that removes easily during routine cleaning. Excessive lint buildup, particularly if it appears compressed or difficult to remove, suggests either inadequate cleaning frequency or potential filter damage that reduces capture efficiency.

Physical damage to the filter structure, such as tears in the mesh, bent frames, or missing sections, compromises filtration effectiveness and allows lint to bypass the filtering system entirely. These conditions create direct pathways for flammable debris to enter the exhaust system, significantly increasing fire risk. Any visible damage warrants immediate dryer lint filter replacement to maintain safe operation.

Replacement and Upgrade Options

Selecting Compatible Filters

Choosing the appropriate replacement dryer lint filter requires careful attention to manufacturer specifications and model compatibility. Using incorrect filters can result in poor fit, inadequate filtration, or restricted airflow that compromises both safety and performance. Most dryers require specific filter dimensions and mounting configurations that must match exactly for proper operation and safety compliance.

Quality replacement filters often exceed original equipment specifications while maintaining full compatibility with existing systems. High-quality aftermarket options may feature improved materials, enhanced durability, or superior filtration efficiency compared to standard factory components. However, any replacement filter must meet or exceed original safety standards and maintain proper airflow characteristics to ensure continued fire prevention effectiveness.

Advanced Filter Technologies

Recent technological developments have introduced enhanced dryer lint filter designs that offer superior fire prevention capabilities while improving overall system efficiency. Some advanced filters incorporate multiple filtration stages, combining coarse pre-filters with fine finishing screens to capture particles of various sizes more effectively. These multi-stage systems can significantly reduce the amount of lint that escapes primary filtration and enters the exhaust system.

Smart filter technologies include indicators that alert users when cleaning or replacement becomes necessary, helping ensure optimal maintenance timing. Some systems incorporate antimicrobial treatments or specialized coatings that resist moisture accumulation and bacterial growth, contributing to healthier indoor air quality in addition to fire prevention benefits. While these advanced options may cost more initially, they often provide enhanced safety margins and longer service life that justify the additional investment.

FAQ

How often should I replace my dryer lint filter

Most dryer lint filter manufacturers recommend replacement every 6 to 12 months, depending on usage frequency and maintenance practices. Heavy-use households may need more frequent replacements, while careful maintenance can extend filter life toward the upper end of this range. Signs that indicate immediate replacement needs include physical damage, persistent lint bypass, or inability to achieve proper cleaning despite thorough washing attempts.

Can I wash my dryer lint filter in the dishwasher

While some dryer lint filter models tolerate dishwasher cleaning, most manufacturers recommend hand washing with warm water and mild detergent to prevent potential damage from high temperatures or harsh detergents. The gentle hand-washing approach allows better control over cleaning intensity and helps preserve filter integrity over multiple cleaning cycles. Always consult your owner's manual for specific cleaning recommendations for your particular filter model.

What happens if I run my dryer without a lint filter

Operating a dryer without a proper lint filter dramatically increases fire risk and can cause significant system damage. Lint will accumulate throughout the internal ductwork, on heating elements, and in the exhaust system, creating multiple ignition points and reducing system efficiency. Most dryer manufacturers void warranties for damage caused by operating without appropriate filtration, and many local fire codes prohibit this unsafe practice.

Are aftermarket dryer lint filters as safe as original equipment

Quality aftermarket dryer lint filters that meet or exceed original equipment specifications provide equivalent safety performance when properly selected and installed. Many aftermarket options actually offer enhanced features or improved materials compared to standard factory components. The key is ensuring compatibility with your specific dryer model and verifying that replacement filters maintain appropriate airflow characteristics and filtration efficiency for safe operation.