A dryer lint filter serves as one of the most critical components in maintaining optimal dryer performance and ensuring safe operation. This essential filtration system captures lint, fabric fibers, and debris that would otherwise accumulate within the dryer's ventilation system, potentially causing significant performance issues and safety hazards. Understanding how a dryer lint filter functions and its impact on overall dryer efficiency can help homeowners maximize their appliance's lifespan while reducing energy costs and fire risks.

Understanding Dryer Lint Filter Functionality

Basic Filtration Process

The dryer lint filter operates through a straightforward yet highly effective mechanism that captures airborne particles during the drying cycle. As heated air circulates through the drum, it picks up moisture and lint from clothing fabrics. This air-lint mixture then passes through the dryer lint filter, which features a fine mesh or screen designed to trap particles while allowing clean air to continue through the exhaust system.

The filtration process relies on the principle of mechanical separation, where the mesh openings are sized to capture lint particles while maintaining adequate airflow. When functioning properly, a dryer lint filter removes approximately 99% of lint and fabric debris from the air stream, preventing these materials from entering the dryer's internal components or external venting system.

Filter Design and Materials

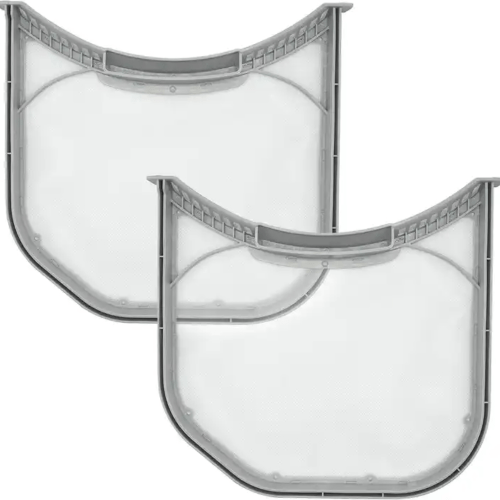

Modern dryer lint filters utilize various materials and construction methods to maximize effectiveness and durability. Most filters feature aluminum or plastic frames with fine metal or synthetic mesh screens that provide optimal balance between filtration efficiency and airflow resistance. The mesh density varies depending on the dryer model and manufacturer specifications, with some filters incorporating multi-layer designs for enhanced particle capture.

Premium dryer lint filter designs often include reinforced edges and corners to prevent tearing during removal and cleaning. Some manufacturers also incorporate antimicrobial treatments into the filter materials to reduce odor-causing bacteria and maintain fresher air circulation throughout the drying process.

Performance Enhancement Benefits

Improved Drying Efficiency

A clean and properly functioning dryer lint filter significantly enhances drying efficiency by maintaining optimal airflow throughout the system. When the filter effectively captures lint and debris, heated air can circulate freely through the drum and exhaust system, ensuring even heat distribution and moisture removal. This improved circulation reduces drying times, which translates to lower energy consumption and reduced wear on clothing fabrics.

Studies indicate that a clogged or damaged dryer lint filter can increase drying times by up to 30%, forcing the appliance to work harder and consume more energy. By maintaining clean filtration, homeowners can achieve consistent drying results while minimizing operational costs and extending the lifespan of both the dryer and clothing items.

Energy Conservation Impact

The energy conservation benefits of a properly maintained dryer lint filter extend beyond simple efficiency improvements. When airflow remains unrestricted, the dryer's heating element operates more effectively, reaching optimal temperatures faster and maintaining consistent heat levels throughout the cycle. This efficiency reduces the overall energy required to complete each load, resulting in measurable savings on utility bills.

Additionally, improved airflow reduces the strain on the dryer's motor and blower components, which consume additional electricity when working against restricted air movement. A quality dryer lint filter ensures these components operate within their designed parameters, maximizing energy efficiency and reducing unnecessary power consumption.

Safety and Maintenance Considerations

Fire Prevention Capabilities

The fire prevention capabilities of a dryer lint filter cannot be overstated, as lint accumulation represents one of the leading causes of residential dryer fires. Lint is highly flammable and can ignite when exposed to the high temperatures generated during normal dryer operation. A functioning dryer lint filter prevents this dangerous material from accumulating in areas where it could come into contact with heating elements or hot surfaces.

Fire safety organizations recommend cleaning the dryer lint filter after every load to maintain optimal safety levels. When filters become clogged or damaged, lint can bypass the filtration system and accumulate in the dryer's internal components, exhaust ducts, or external venting areas, creating significant fire hazards that may go unnoticed until dangerous conditions develop.

Regular Maintenance Requirements

Proper maintenance of a dryer lint filter involves more than simple lint removal after each use. Regular inspection for tears, holes, or mesh damage ensures continued filtration effectiveness and prevents lint from bypassing the system. Monthly deep cleaning with warm soapy water removes fabric softener residues and other substances that can clog the mesh openings over time.

Replacement of the dryer lint filter becomes necessary when cleaning cannot restore proper function or when physical damage compromises the filter's integrity. Signs that indicate replacement needs include persistent lint in the dryer drum after cleaning, reduced airflow during operation, or visible damage to the filter frame or mesh material.

Technical Performance Metrics

Airflow Optimization

The technical performance of a dryer lint filter directly correlates with its ability to maintain optimal airflow rates while providing effective filtration. Engineering specifications typically measure filter performance in terms of pressure drop across the filter media, with lower pressure drops indicating better airflow characteristics. Quality filters achieve high filtration efficiency while minimizing resistance to air movement.

Airflow optimization also depends on the filter's physical dimensions and installation method. Properly sized dryer lint filter units ensure complete coverage of the air intake area without gaps that could allow unfiltered air to bypass the system. Secure mounting mechanisms prevent filter displacement during operation, which could compromise both filtration and airflow performance.

Filtration Efficiency Standards

Industry standards for dryer lint filter performance establish minimum efficiency requirements for particle capture across different size ranges. These standards ensure that filters effectively remove lint particles while maintaining adequate service life under normal operating conditions. Premium filters often exceed minimum standards, providing enhanced protection and longer service intervals.

Testing protocols evaluate filter performance under various conditions, including different lint types, moisture levels, and airflow rates. This comprehensive testing ensures that dryer lint filter products perform consistently across diverse operating environments and usage patterns, providing reliable protection and performance enhancement for residential and commercial applications.

Installation and Compatibility Factors

Proper Installation Procedures

Correct installation of a dryer lint filter ensures optimal performance and prevents operational issues that could compromise safety or efficiency. The installation process typically involves removing the old filter, cleaning the filter housing area, and securely positioning the new filter according to manufacturer specifications. Proper alignment prevents air leaks that could reduce filtration effectiveness.

Installation procedures may vary depending on the dryer model and filter design, with some units featuring slide-in mechanisms while others require specific mounting hardware. Following manufacturer guidelines ensures that the dryer lint filter operates as designed and maintains warranty coverage for both the filter and the dryer appliance.

Model Compatibility Requirements

Selecting the correct dryer lint filter requires careful attention to model compatibility and dimensional specifications. Different dryer manufacturers utilize various filter sizes, mounting methods, and performance requirements, making it essential to match the replacement filter to the specific appliance model. Incompatible filters may not provide adequate coverage or could create installation difficulties.

Compatibility information typically includes part numbers, dimensional measurements, and performance specifications that must match the original equipment. Some aftermarket dryer lint filter options offer universal compatibility across multiple models, while others are designed for specific manufacturer lines or individual appliance models.

Economic and Environmental Benefits

Cost-Effectiveness Analysis

The cost-effectiveness of maintaining a quality dryer lint filter extends well beyond the initial purchase price, encompassing energy savings, reduced maintenance costs, and extended appliance lifespan. Regular filter maintenance and timely replacement prevent costly repairs that could result from lint accumulation in dryer components or ventilation systems.

Economic analysis demonstrates that the investment in a proper dryer lint filter typically pays for itself within months through reduced energy consumption and improved drying efficiency. Additional savings result from reduced clothing wear, fewer repair calls, and extended dryer lifespan, making filter maintenance one of the most cost-effective appliance care practices.

Environmental Impact Reduction

Environmental benefits of effective dryer lint filter maintenance include reduced energy consumption, which translates to lower carbon emissions and decreased demand on power generation systems. Improved dryer efficiency means fewer resources required for each load of laundry, contributing to overall sustainability efforts in household operations.

The extended lifespan of dryers equipped with properly maintained filters also reduces the environmental impact associated with appliance manufacturing and disposal. By maximizing the useful life of existing equipment, homeowners contribute to resource conservation and waste reduction while maintaining optimal performance levels.

FAQ

How often should I clean my dryer lint filter

You should clean your dryer lint filter after every single load of laundry to maintain optimal performance and safety. This frequent cleaning prevents lint buildup that can restrict airflow, increase drying times, and create fire hazards. Additionally, perform a deeper monthly cleaning with warm soapy water to remove fabric softener residues and other substances that can clog the mesh over time.

What are the signs that my dryer lint filter needs replacement

Signs that your dryer lint filter needs replacement include visible tears or holes in the mesh, persistent lint accumulation in the dryer drum even after cleaning, reduced airflow during operation, damaged or bent filter frames, and inability to remove lint effectively during routine cleaning. If cleaning with soap and water doesn't restore proper function, it's time for a replacement.

Can a damaged dryer lint filter cause my dryer to overheat

Yes, a damaged dryer lint filter can definitely cause overheating issues. When the filter is torn or clogged, it restricts airflow through the system, forcing the dryer to work harder to maintain proper drying temperatures. This restricted airflow can cause heat to build up within the appliance, potentially triggering thermal safety switches or creating dangerous conditions that could lead to component failure or fire hazards.

Are aftermarket dryer lint filters as effective as original equipment parts

High-quality aftermarket dryer lint filters can be just as effective as original equipment parts when they meet proper specifications for your dryer model. The key factors are correct dimensions, appropriate mesh density, and quality construction materials. Always verify compatibility with your specific dryer model and choose reputable manufacturers that provide filters meeting or exceeding original equipment standards for filtration efficiency and durability.